Bambu Lab Support for PLA / PETG / ABS

Price range: RM59.00 through RM349.00

| Key Specifications | |

|---|---|

| Printing Temperature | 190–240 ºC |

| Bed Temperature | 35–60 ºC |

| Printing Speed | < 100 mm/s |

| Chamber Temperature | 25–45 ºC |

| Density | 1.28 g/cm³ |

Order Info

- Order will be shipped out from our KL warehouse in 1-3 business days once being processed.

- If you need Lalamove once purchased, WhatsApp to our phone for quick arrange delivery.

Bambu Lab Support Filament for PLA/PETG/ABS – Easy Peel-Off Breakaway Support Material

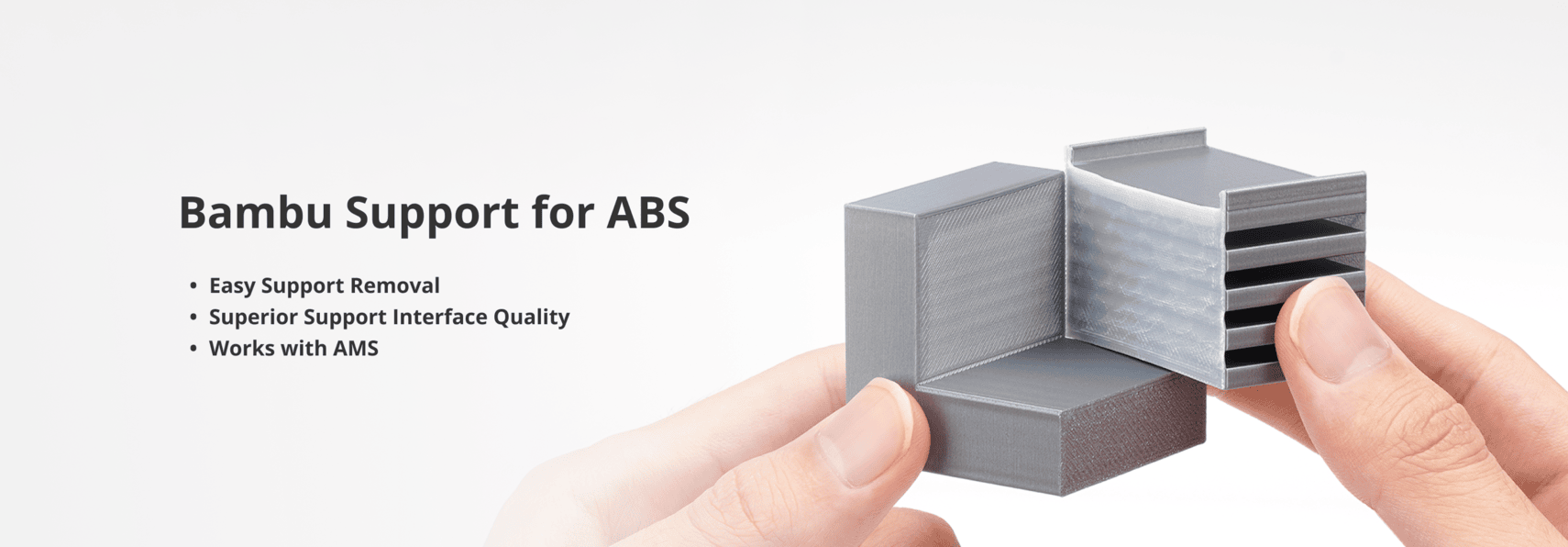

Bambu Lab Support Filament is a specialized breakaway support material designed for effortless, tool-free removal from PLA, PETG, and ABS prints. The specially formulated material minimizes fusion with your main filaments, allowing supports to cleanly separate without damaging surface quality. At 34% less cost than previous versions, it delivers premium results at an affordable price.

Perfect for complex prints with overhangs, bridges, and intricate details. RFID-enabled for automatic settings and fully compatible with AMS and AMS Lite systems.

Bambu Lab Support Filament Key Features

- Effortless Peel-Off – Remove by hand without tools

- Residue-Free Separation – Clean break from prints

- 34% Lower Cost – More affordable than previous version

- Multi-Material Compatible – Works with PLA, PETG, and ABS

- RFID & AMS Compatible – Works with AMS and AMS Lite

- Interface-Only Option – Use only where needed

Bambu Lab Support Filament Printing Parameters

| Parameter | Recommended Value | Notes |

|---|---|---|

| Nozzle Temperature | 230°C | Both initial and other layers |

| Bed Temperature | 60°C | For all plate types |

| Drying | 75°C for 8 hours | If brittle or moisture exposed |

| Slicer Setting | Support/Raft Interface | Select in Bambu Studio |

| Top Interface | 0mm | For best results |

| Z-Distance | 0mm | For best results |

Slicer Configuration (Bambu Studio)

| Setting | Configuration |

|---|---|

| Support/Raft Interface | Select “Support for PLA/PETG” or “Support for ABS” |

| Interface-Only Mode | Enable for efficient material usage |

| Tree Supports | Avoid using support filament for “Support/raft base” |

Support Filament Applications

- Complex Overhangs – Support steep angles cleanly

- Bridges – Prevent sagging on long spans

- Intricate Details – Preserve fine features

- Multi-Material Prints – AMS-enabled dual extrusion

- Batch Production – Consistent quality across prints

- Professional Prototypes – Clean surfaces without post-processing

Support Filament Tips

- Interface-Only Mode – Enable for efficient material usage.

- 0mm Settings – Use 0mm top interface and Z-distance for best separation.

- Avoid Tree Support Base – Don’t use for “Support/raft base” with tree supports.

- Store Dry – Keep sealed; dry at 75°C for 8 hours if brittle.

- RFID Auto-Settings – AMS automatically configures optimal parameters.

Bambu Lab Support Filament Specifications

| Brand | Bambu Lab |

| Material | Breakaway Support Material |

| Diameter | 1.75mm |

| Compatible With | PLA, PETG, ABS |

| RFID Enabled | Yes (AMS & AMS Lite compatible) |

| Removal Method | Hand peel-off (no tools needed) |

| Cost Savings | 34% less than previous version |

Bambu Lab Support Filament FAQ

Q: How does the support separate so easily?

A: The support filament is formulated to minimize fusion with PLA and PETG due to differences in polarity, allowing clean separation without damaging the print surface.

Q: Do I need to use support filament for the entire support structure?

A: No! Enable “Interface-Only Mode” in Bambu Studio to use support filament only on contact surfaces, saving material and time.

Q: Is this compatible with AMS Lite?

A: Yes, the Support Filament works with both AMS and AMS Lite systems with RFID auto-detection.

Q: What if the support is hard to remove?

A: Check your slicer settings – use 0mm top interface and 0mm Z-distance. Also ensure the filament is dry; wet filament can bond more strongly.

Q: Can I use this with third-party filaments?

A: While optimized for Bambu Lab filaments, it can work with other PLA, PETG, and ABS. Results may vary with non-Bambu materials.

Related Products

Looking for other support materials or multi-material solutions? Explore our collections:

- PVA Support Filament – Water-soluble support

- All Support Materials – More options

- Bambu Lab PLA – Compatible main materials

- AMS-Compatible Filaments – Multi-material printing

| Weight | 0.80 kg |

|---|---|

| Dimensions | 25.00 × 25.00 × 7.00 cm |

| Variation | Support for PLA, Support for PLA/PETG, Support for ABS |

| Size | 0.5kg, 1kg |

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.