Bambu Lab H2D

RM9,499.00 – RM15,999.00

Product Features

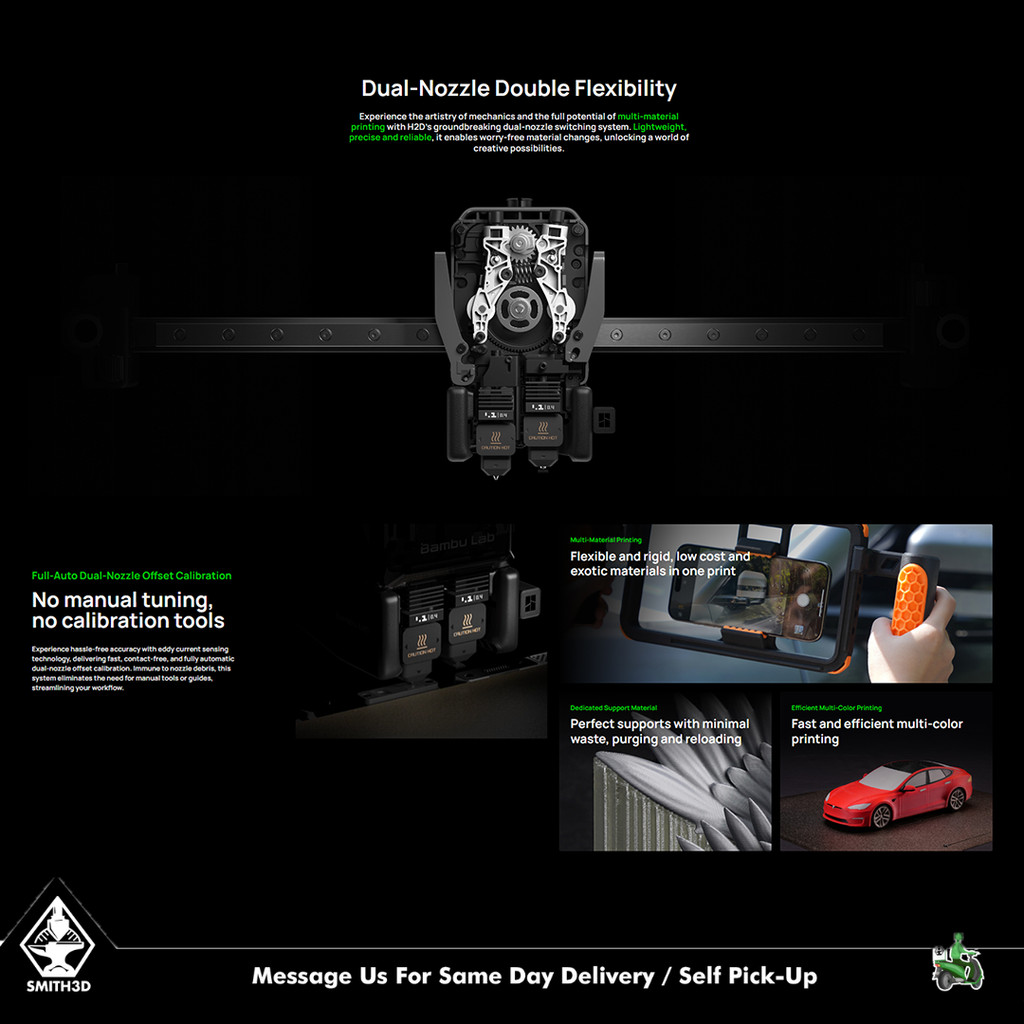

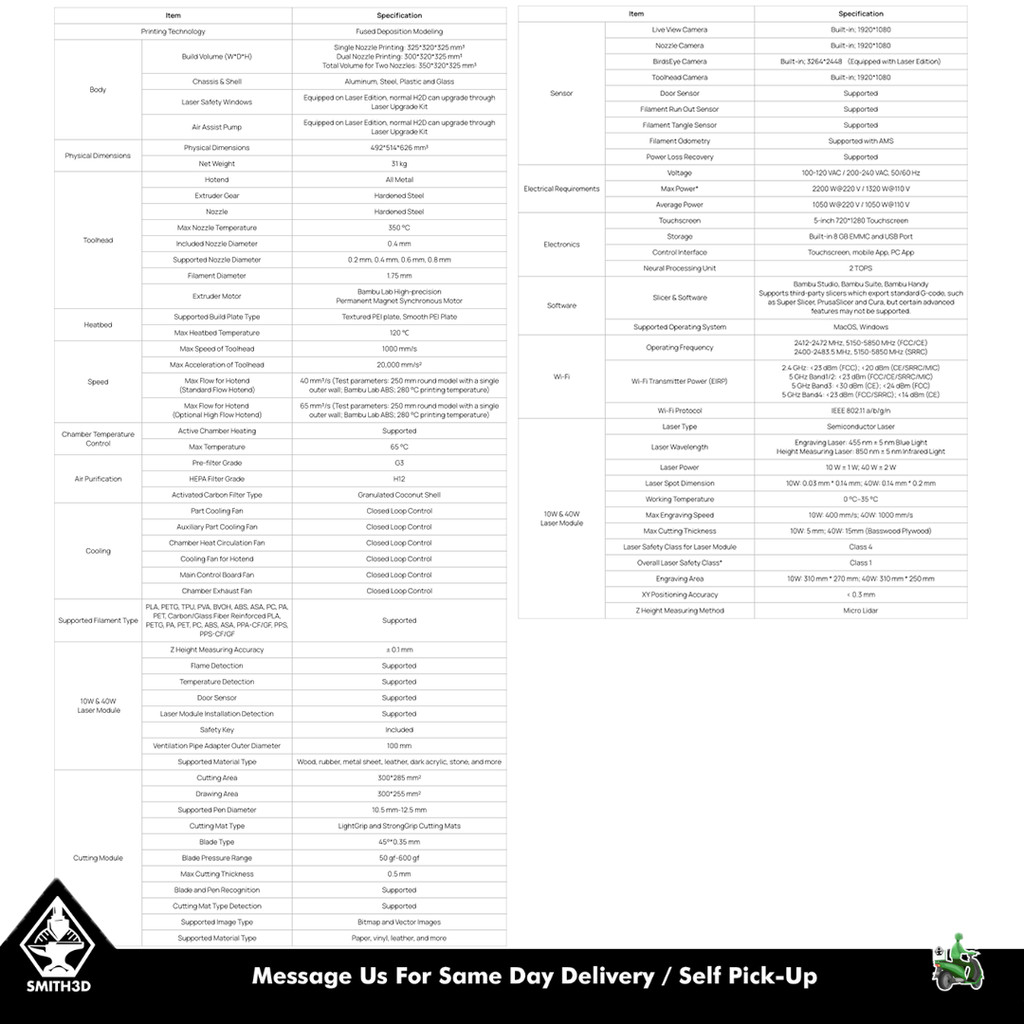

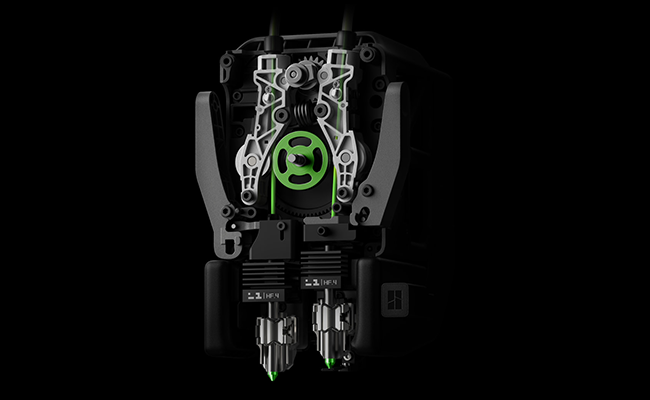

- Dual-nozzle multi-material 3D printing

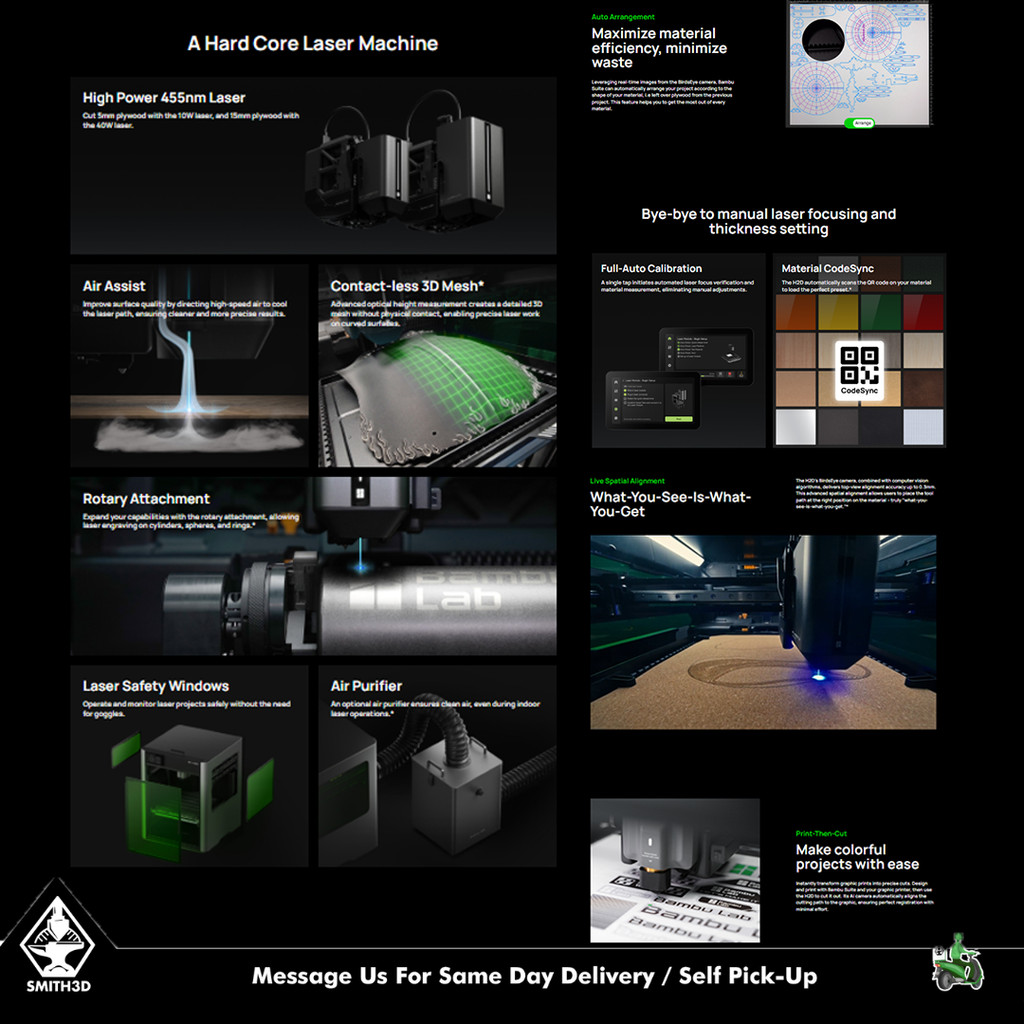

- Optional 10W/40W laser and cutting module

- 350 × 320 × 325 mm³ print volume

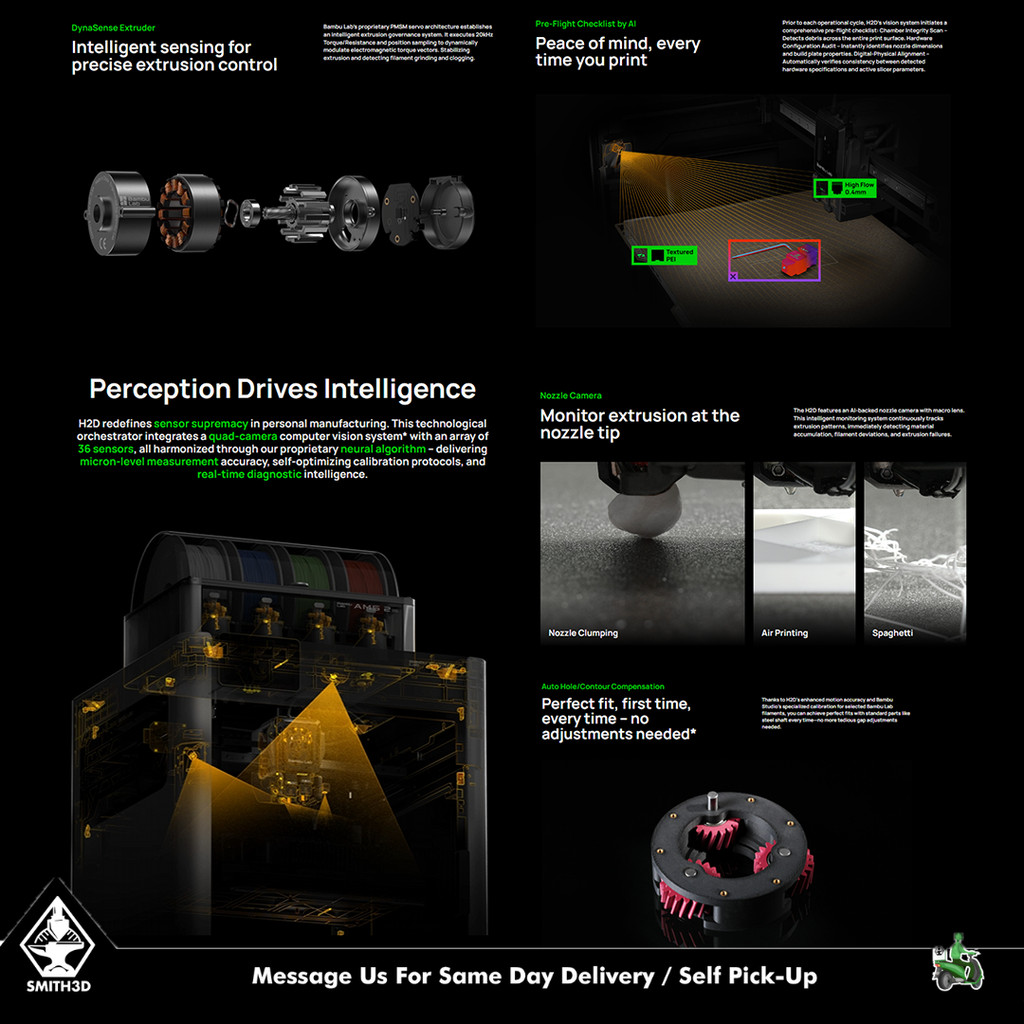

- 5 μm resolution optical motion calibration

- Closed-loop servo extruder

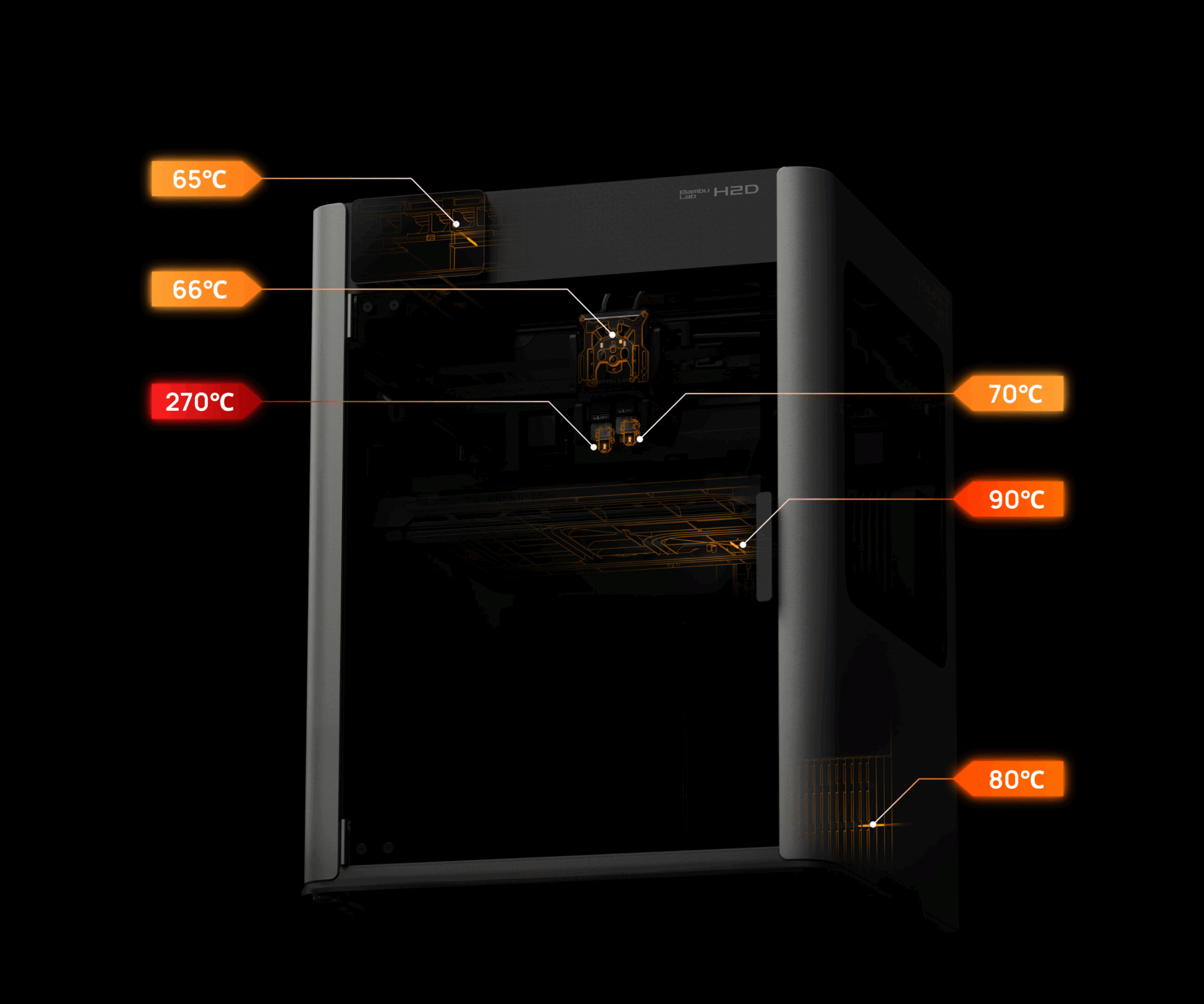

- 350 °C nozzle & 65 °C active chamber heating

Order Info

- Order will be shipped out from our KL warehouse in 1-3 business days once being processed.

- If you need Lalamove once purchased, WhatsApp to our phone for quick arrange delivery.

Rethink Personal Manufacturing

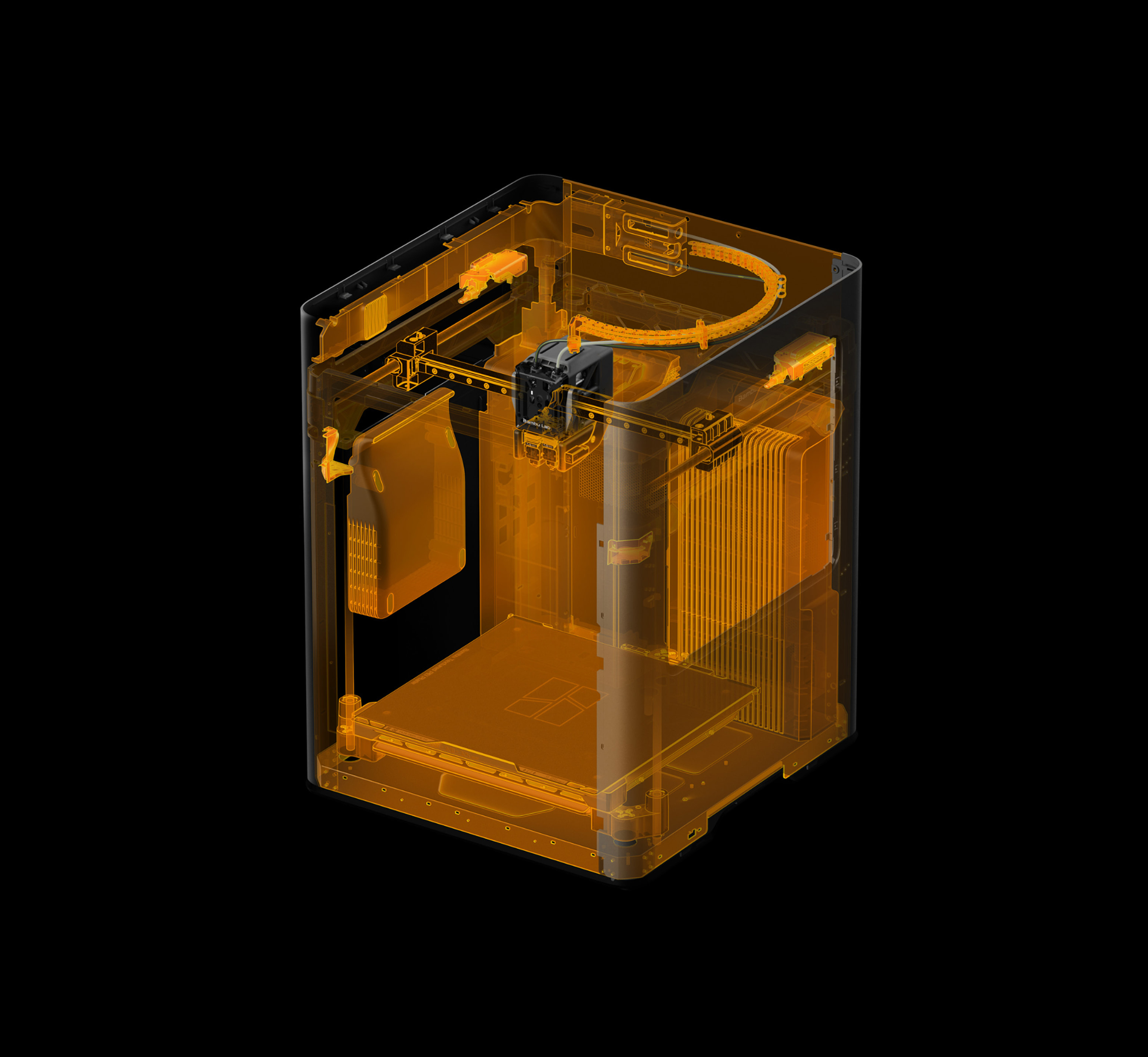

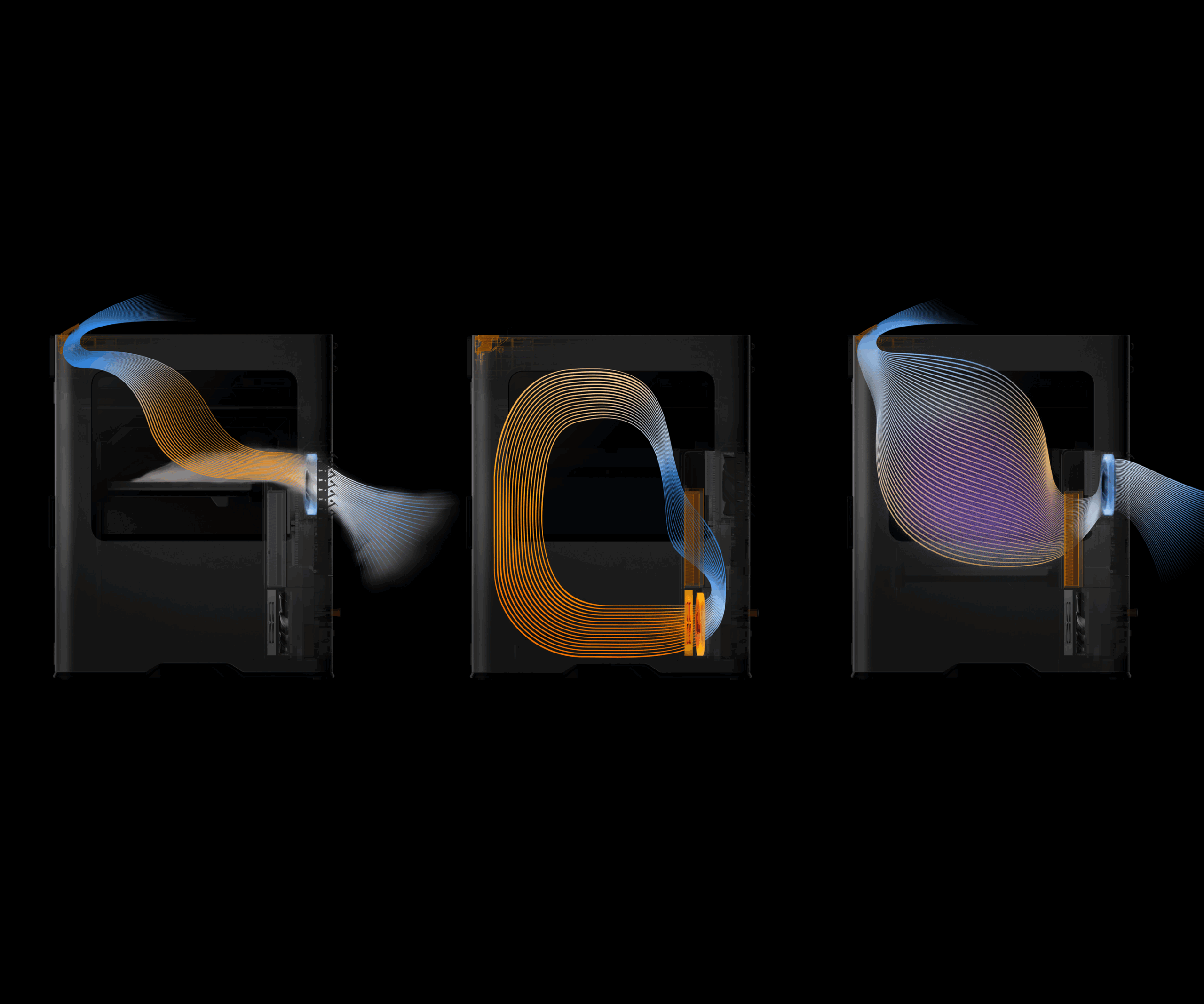

H2D is not only a 3D printer, it adds laser engraving and cutting (separate add-on), digital cutting and plotting to your studio (separate add-on), unlocking new creative possibilities.

All-In-One Personal Manufacturing Hub

Revolutionizing Accuracy - One order of magnitude higher motion accuracy.

Dual-Nozzle, Double Flexibility - Fast and efficient multi-material printing!

4 computer vision cameras*, 36 sensors, 2 servo motors united by sophisticated algorithm for your simplicity.*

Next-Gen Filament Management - Drying, feeding and storage in a single package.

| Weight | 46.20 kg |

|---|---|

| Dimensions | 63.00 × 63.00 × 76.00 cm |

| Variation | H2D Only, H2D AMS Combo, H2D AMS 10W Laser Combo, H2D AMS 40W Laser Combo |

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.